Inside YOKE's Smart Factory: Automation Enhancing Quality and Efficiency

Inside YOKE's Smart Factory

Automation Enhancing Quality and Efficiency

Production at YOKE Industrial Corp. started in 1997.

A lot has changed since, as we’ll explore. What hasn’t, is that there are long-term career opportunities in an ever-evolving manufacturing environment.

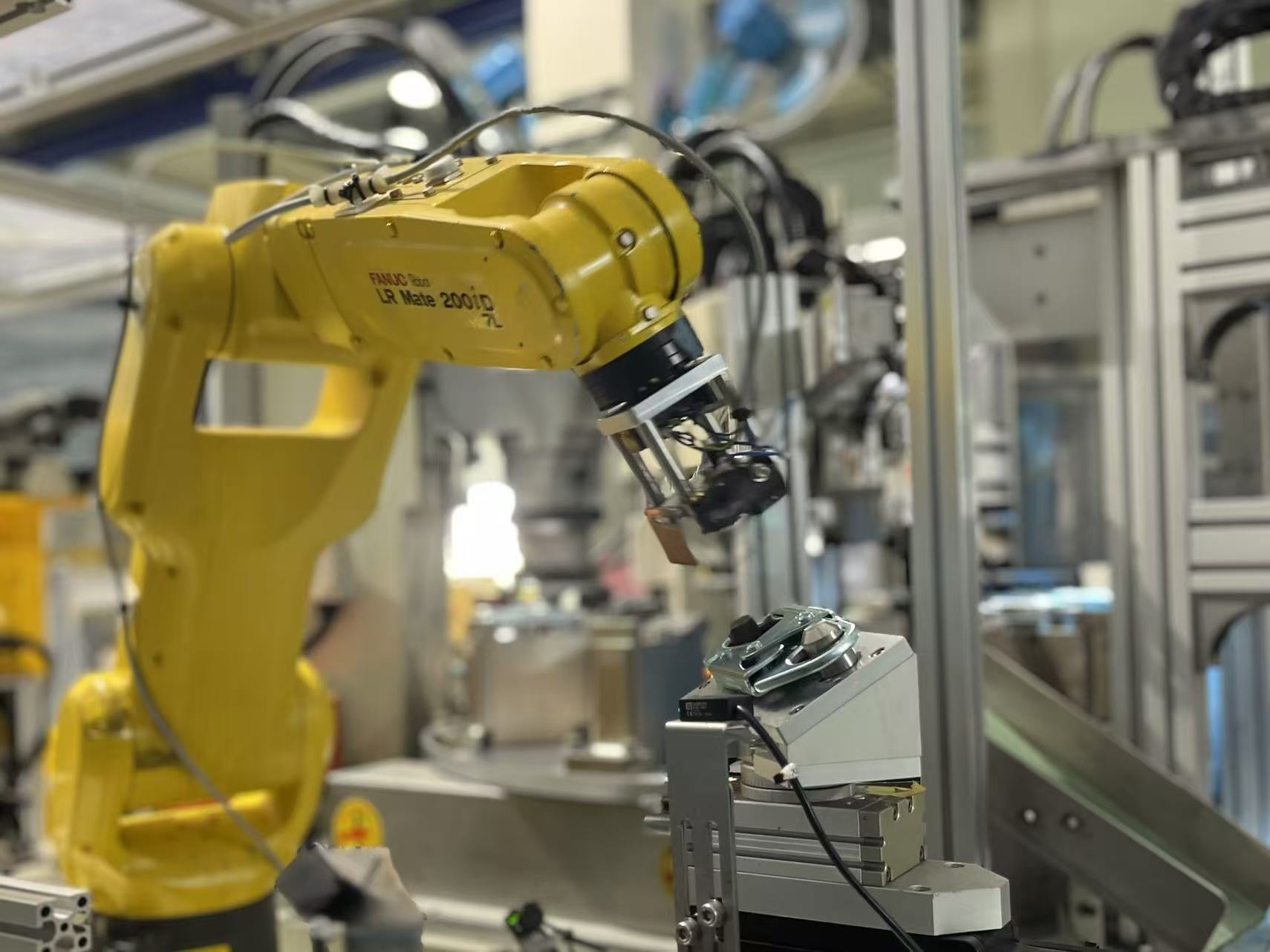

YOKE’s approx. 56,000 square-metre facility produces a staggering 20 million pieces per year. The smart factory is built on 71 automation systems with 108 robotic arms;

it is an automated fleet of state-of-the-art Fanuc equipment, that represents approx. US$30m worth of investment. In October 2024, for example, the total time of robotics operation topped 5,176 hours.

Importantly, the factory, located in Taiwan, also employs 500 employees, while human workforce numbers globally are on a steady upward trajectory.

As Steven Hong, the company's president, says, “We aim to achieve regional business services through the expansion of expatriate staff.”

It's been nearly 14 years since Hong took what was an unprecedented step at the time, into the world of robotics, with a two-tiered belief that still endures today:

A fast in-and-out operational mindset and the companies that can solve handling and fast inventory management in the future will be the winners.

Even today, a dedicated department is constantly evaluating and designing future smart factory installations.

The pace of automation implementation will never stop

“The pace of automation implementation will never stop,” says Hong,

“And many people are discussing the feasibility of introducing automation into various processes every day.”

Despite such a wholesale commitment to robotics and automation, YOKE staff numbers have not decreased.

“On the contrary,” says Hong. “Because of the expansion in production capacity, we have continued to add staff.

However, the criteria for recruitment has changed, due to modifications in production and management models.”

The overall operation serves as proof that humans and robots are most efficient together.

The automation systems introduced by YOKE are aimed at stabilising product quality, reducing reliance on personnel, and enhancing the value of employees.

While production efficiency may not necessarily always improve, as robots are difficult to fully replace human hands, the benefits are clear:

Stable quality/Stable production volume/ Enhanced employee value

Humans and Robots, Better Together

The overall operation serves as proof that humans and robots are most efficient together. The automation systems introduced by YOKE are aimed at stabilising product quality, reducing reliance on personnel, and enhancing the value of employees. While production efficiency may not necessarily always improve, as robots are difficult to fully replace human hands, the benefits are clear:

- Stable quality

- Stable production volume

- Enhanced employee value

Climb to the summit

As YOKE's fleet of robots has grown — from those stacking finished products onto pallets to AOI and everything in between — so too has the prevalence of the Fanuc logo, the iconic badge of the Japanese robotics company.

Fanuc is one of the largest industrial robot manufacturers in the world, holding approximately 30% of the global market share. It is located at the foot of Mount Fuji in Japan, with over 5,000 robotic arms in use at its facility.

Hong says, “YOKE believes in the compounding effect of strong partnerships, and trusts that Fanuc can provide appropriate solutions for each manufacturing process as we implement automation.

We are committed to advancing manufacturing by integrating both automation and digitalisation. We believe digitalisation is essential for improving efficiency, product quality, and staying competitive in the future.

By implementing smart sensors, cloud-based platforms, and data analytics, we can optimise production processes and make data-driven decisions.

While not claiming to be the sole leader, we strive to be at the forefront of this digital and automation transformation in the industry.”

YOKE's growth, through robotics and ongoing personnel recruitment, is an example to follow for other manufacturing businesses, in lifting and other sectors.