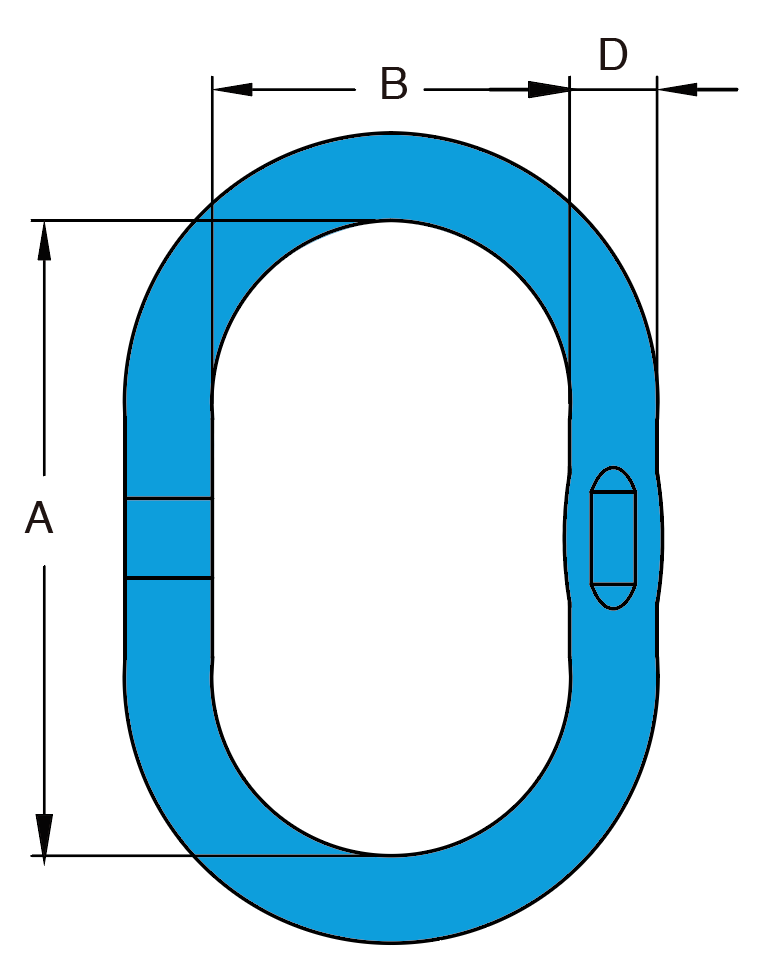

G-100 Welded Master Link

Item No.X-002

• Quenched and Tempered Alloy Steel.

• At least 25% greater WLL than traditional G80products.

• Manufactured in accordance with ASTM A952/A952M, ASME B30.9, ASME B30.26, EN 1677-4 and OSHA 1910.184.

• Proof Load tested at 2.5 times the WLL with certification for each batch manufactured.

• Design Factor 4:1.

• Fatigue rated to 20,000 cycles at 1.5 times the WLL.

• Tempering temperature at a minimum of 400°C.

• Welded Master Link designed for 1-2 legs Chain, Wire Rope and Webbing Slings.

• Each link is marked with batch number that links to the test certificate

• At least 25% greater WLL than traditional G80products.

• Manufactured in accordance with ASTM A952/A952M, ASME B30.9, ASME B30.26, EN 1677-4 and OSHA 1910.184.

• Proof Load tested at 2.5 times the WLL with certification for each batch manufactured.

• Design Factor 4:1.

• Fatigue rated to 20,000 cycles at 1.5 times the WLL.

• Tempering temperature at a minimum of 400°C.

• Welded Master Link designed for 1-2 legs Chain, Wire Rope and Webbing Slings.

• Each link is marked with batch number that links to the test certificate

| Item NO. | Compare | Code No | For Grade 100 Chain | WLL β 0-45° | Proof Load | Used to single hook according to DlN 15401 NO. | Dimensions | ||

|---|---|---|---|---|---|---|---|---|---|

| 1-leg | 2-leg | tonnes | kN | A | D | ||||

| X-002-13 | Compare | BD-13 | 7,8 | 6 | 2.8 | 69 | 2.5 | 110 | 13 |

| X-002-16 | Compare | BD-16 | 10 | 7,8 | 4 | 98 | 2.5 | 110 | 16 |

| X-002-19 | Compare | BD-19 | 13 | 10 | 6.7 | 164 | 5 | 135 | 19 |

| X-002-22 | Compare | BD-22 | 13 | 10 | 8.5 | 208 | 6 | 160 | 22 |

| X-002-28 | Compare | BD-28 | 16 | 13 | 11.5 | 282 | 8 | 180 | 28 |

| X-002-32 | Compare | BD-32 | 20 | 16 | 17 | 417 | 10 | 200 | 32 |

| X-002-36 | Compare | BD-36 | 22 | 20 | 25.1 | 615 | 16 | 260 | 36 |

| X-002-45 | Compare | BD-45 | 26 | 22 | 38.3 | 938 | 25 | 300 | 45 |

| X-002-50 | Compare | BD-50 | 32 | 26 | 45 | 1103 | 32 | 300 | 50 |

| Item NO. | Compare | Code No | For Grade 100 Chain | WLL β 0-45° | Proof Load | Used to single hook according to DlN 15401 NO. | Dimensions | ||

|---|---|---|---|---|---|---|---|---|---|

| 1-leg | 2-leg | lbs | lbs | A | D | ||||

| X-002-45 | Compare | BD-45 | 1 | 7/8 | 84400 | 211000 | 25 | 11.81 | 1.77 |

| X-002-50 | Compare | BD-50 | 1-1/4 | 1 | 99200 | 248000 | 32 | 11.81 | 1.97 |

| X-002-16 | Compare | BD-16 | 3/8 | 1/4-5/16 | 8800 | 22000 | 2.5 | 4.33 | 0.63 |

| X-002-19 | Compare | BD-19 | 1/2 | 3/8 | 14700 | 36750 | 5 | 5.31 | 0.75 |

| X-002-22 | Compare | BD-22 | 1/2 | 3/8 | 18700 | 46750 | 6 | 6.3 | 0.87 |

| X-002-28 | Compare | BD-28 | 5/8 | 1/2 | 25300 | 63250 | 8 | 7.09 | 1.1 |

| X-002-32 | Compare | BD-32 | 3/4 | 5/8 | 37400 | 93500 | 10 | 7.87 | 1.26 |

| X-002-36 | Compare | BD-36 | 7/8 | 3/4 | 55300 | 138250 | 16 | 10.24 | 1.42 |

| X-002-13 | Compare | BD-13 | 1/4-5/16 | 7/32 | 6100 | 15250 | 2.5 | 4.33 | 0.51 |

__25L10vYn25.jpg)

__25L10qOeEJ.jpg)

__25L10qOeEJ.jpg)